Bulkhead Systems

CargoLite

CargoLite is a lightweight flexible bulkhead system suitable for establishing different temperature compartments in panel vans/home delivery vehicles.

Application Field

The CargoLite Bulkhead System is suitable for panel vans/home delivery vehicles and allows for establishing different temperature compartments.

Fabrication

> PVC skin bonded to insulating foam

> Corners are double reinforced; 100% PVC construction for increased life

> Side seals are individually sealed to prevent moisture migration to the core in the event of side

seal damage

> The bulkhead is designed in a way that it is larger than the inside of the vehicle. Side, top and

bottom seals offer compression to reduce the chance of temperature leakage

> Handles are fitted as standard to facilitate ease of handling

> Light to handle, weighing in at only 15 kgs (depending on the specification)

> Every unit made to measure

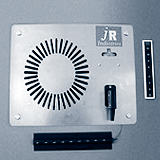

> Option: controlled fan kit, air flow of 400cm³/hour, digital temperature read-out, adjuster to set

temperature to required level

> Available in single span or bi-fold form

LoadMaker 1300

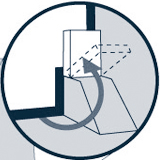

The LoadMaker 1300 driver friendly easylift system is two bulkheads in one and stands out for its easy lifting and lowering. The bulkhead panel swings to the side of the body for easy passage from ambient to chilled and from chilled to frozen compartments. For establishing different temperature compartments in a single compartment trailer, our easylift system is the most multifunctional and cost-effecitve option for both chilled transport and combined logistics. The system comes as an assembly kit, prepared for an easy and quick installation.

Application Field

The LoadMaker Bulkhead System is particularly used in single compartment trailers with different temperature requirements, where different foodstuffs are required to be carried at different temperatures. This multi-compartment transport has become increasingly popular throughout Europe as changing consumption patterns coupled with both legislative and retailer quality requirements have had their effect.

Advantages

> Available in bi-fold or single span

> Light to handle; each section weights approx. 18 kgs

> Easy operation and installing/removal; roof mounted, if required

> Unlike the bi-fold, the roof mounted LoadMaker stays in the vehicle when not in use

Fabrication

> Bi-fold system for an easy loading and unloading

> The Bulkhead moves on track system which allows flexibility in establishing ambient, cold and

frozen compartments.

> The easylift system leaves one panel closed during unloading to minimize cold air loss

> Extremely durable, capable of withstanding impact damage

> Lifting device is simple and safe to use; it raises and lowers Bulkheads safely, individually or

together

> Easy one man operation

System D

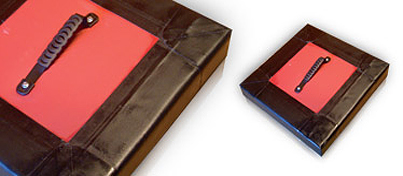

The System D is the flexible Bulkhead system with split panels and is available as 1 piece, bi-fold or plug. It offers multi-options for your bespoke application, including fans. Normally a 50/50 split, this makes the System D driver and loader friendly, effectively halving the effort to open and close - particularly with the all stainless steel Lift & Stow device.

Application Field

The System D is particularly used in chilled and freezer bodies with different temperature compartments, where different foodstuffs are required to be carried at different temperatures. This multi-compartment transport has become increasingly popular throughout Europe as changing consumption patterns coupled with both legislative and retailer quality requirements have had their effect.

Advantages

> Extreme durability

> Roof mounted type available

> Multi-options for your bespoke application incl. fans

> Split panels can be moved independently of one another

> Hygienic and easy to clean

Fabrication

> Lightweight construction

> New core eliminates sagging

> Waterproof materials throughout

> Extra tough bonded PVC skin

> Easy lifting and lowering device in ergonomic design using high quality marine grade components

housed in a robust stainless steel fabrication

> Using a 10 mm Ø braid polyester rope, the movement of the Bulkhead requires minimum effort

> When not in use this can be stowed into its bungee carrier